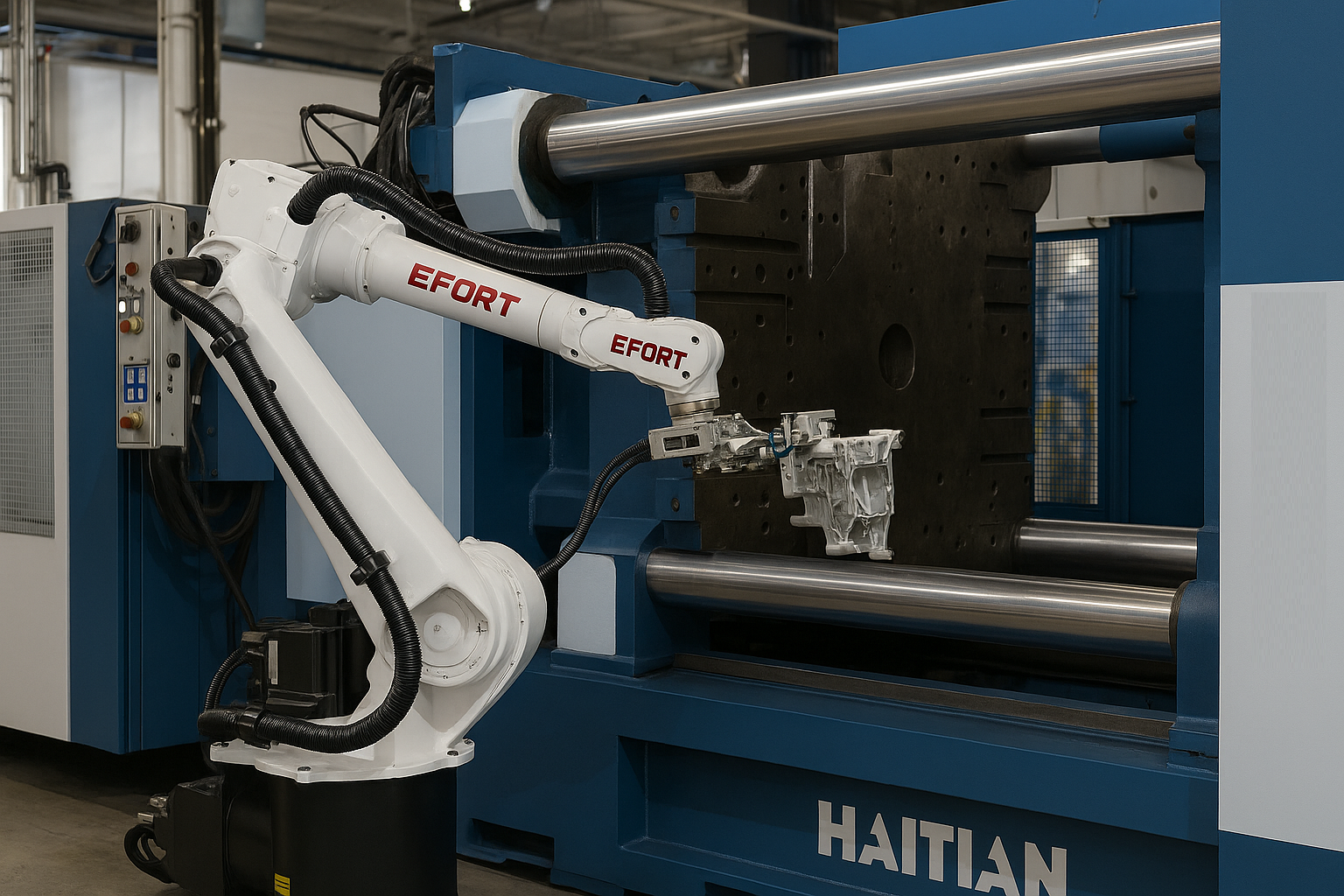

The die casting industry is undergoing a deep transformation: productivity, traceability, energy efficiency, and digital integration are now key factors for staying competitive. To meet these challenges, Mambretti Metalli offers a technologically advanced and fully integrated solution:

automated workcells composed of Efort Robots and Haitian presses.

These workcells are proving highly successful in the die casting sector, thanks to their ability to automate, digitize, and optimize the entire production process.

🔩 A Proven Combination: Efort Robots + Haitian Presses

Efort Robots

-

6-axis articulated robots, payloads from 3 kg to 500 kg

-

Repeatability up to ±0.05 mm, ideal for mold handling and part removal

-

Integrated with Siemens, Fanuc, EtherCAT, and Profinet controls

-

Customizable multi-grippers for loading/unloading, core pulling, trimming, deburring

-

Also available in collaborative versions for hybrid man-machine stations

Haitian Presses

-

Two-platen servo-hydraulic die casting machines, with clamping forces from 5,500 to 88,000 kN

-

Compact closed-column design for optimal use of factory space

-

High-performance injection unit for fast and precise cycles

-

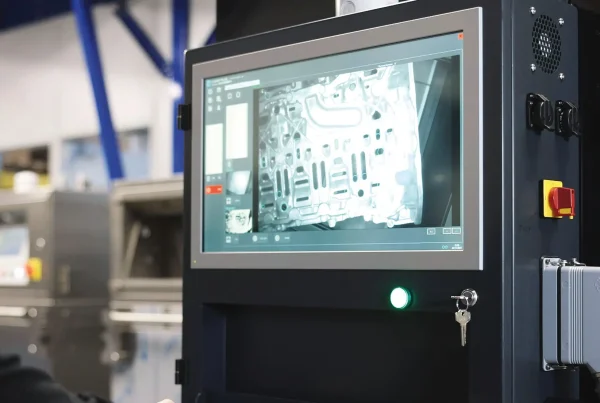

Intelligent KEBA controller with 18.5″ touchscreen and real-time diagnostics

-

Fully compatible with OPC-UA/Euromap protocols for Industry 4.0

🤖 Smart Automation Ready for Industry 5.0

These workcells are already running successfully in several Italian facilities, delivering clear benefits:

-

Cycle time reduction up to 25%

-

Lower reliance on manual labor and improved safety

-

Scrap reduction thanks to accurate handling and integrated quality checks

-

Remote monitoring and predictive maintenance via PLC and smart sensors

-

Native integration with MES and digital factory systems

💡 Fiscal Incentives: Immediate ROI

The Efort + Haitian workcells fully meet the eligibility criteria for Industry 4.0 investments, and thanks to their digital and energy-saving features, they also qualify for Industry 5.0 benefits.

Available incentives (2025):

-

Tax credit up to 40% under the Italian Industry 4.0 Plan

-

Up to 45% incentives for green and digital investments under the Industry 5.0 scheme

-

Higher scores in regional funding calls focused on innovation and sustainability

🔧 Full Cycle Partner: Mambretti Metalli

Mambretti Metalli is more than a supplier — we support our clients across every phase:

-

Technical consulting to define the ideal configuration

-

Workcell layout design based on your factory floor

-

On-site installation, testing, and operator training

-

After-sales support, spare parts and remote assistance

Thanks to a solid international network and deep experience in metal processing, Mambretti Metalli is a trusted partner for advanced automation in die casting.

🎥 See the Workcells in Action

Visit our video section on Youtube to watch real installations of Efort + Haitian robotic workcells operating in die casting environments.

See for yourself:

-

synchronized robot and press interaction

-

fast, fluid movements

-

complete safety in demanding production settings