Mambretti Tech is pleased to announce that it is officially a distributor of EFORT Robots for use in metal die-casting production processes.

EFORT Intelligent Robot Co.,Ltd is a Chinese company founded in 2007 and headquartered in Wuhu, approximately 350 kilometers west of Shanghai. It is one of China’s leading manufacturers of anthropomorphic industrial robots, with a turnover of €250 million and 16,000 robots placed on the Chinese market in 2024. These robots have applications across a wide range of industries, including automotive, electronics, photovoltaic energy, lithium batteries, metal products, furniture, home appliances, and food and beverages.

In recent years, EFORT has expanded its international presence through strategic acquisitions in Italy. It has integrated companies such as Webb Robotica (Venice), Evolut (Brescia), CMA Robotics (Udine), Robox (Novara), and WFC Group (Turin) into its group, thereby strengthening its position in the European industrial robotics and automation market.

EFORT W.F.C. acts as the group’s operational holding company for the international market, specializing in the design and implementation of customized industrial automation systems for various sectors. Furthermore, EFORT Robotics focuses on the promotion and distribution of EFORT products in the EMEA region (Europe, the Middle East, and Africa), leveraging a network that spans various European countries, the Mediterranean regions, and North Africa.

Marketed Robot Models

EFORT offers a wide range of industrial robots designed to meet various production needs.

Here is an overview of the main models suitable for foundry applications, featuring pressurized motors, soft servo, and simplified programming.

Note: Naming convention used – ER (maximum payload in kg) – (reach in mm):

Mini Robots

- ER3-600: A compact 6-axis robot with a 600 mm reach, ideal for assembly tasks and handling small components.

Light Payload Robots

- ER7-700: Designed for light loads, with a 700 mm reach, suitable for pick-and-place and light assembly applications.

- ER12-2100: A versatile robot with a 2100 mm reach, used in welding and handling processes.

Medium Payload Robots

- ER25-1800: With a 25 kg payload capacity and 1800 mm reach, ideal for handling and assembly operations.

- ER35-1800: Offers higher payload capacity while maintaining a 1800 mm reach, suitable for more demanding applications.

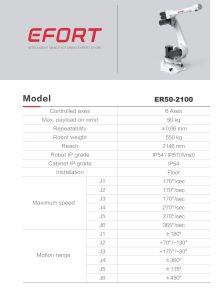

- ER50-2100 – ER70-2100: Payload capacities of 50 kg and 70 kg respectively, both with a 2100 mm reach.

Heavy Payload Robots

- ER150-2700: Designed for heavy-duty applications with a payload capacity of up to 150 kg and a reach of 2700 mm, commonly used for heavy material handling and palletizing.

- ER210-2700: With a 210 kg payload and 2700 mm reach, this model is ideal for tasks requiring both strength and precision.

SCARA Robots: Suitable for industries such as electronics manufacturing, lithium batteries, automotive electronics, and photovoltaics.

- ESR3-400Z15: With a 400 mm reach, ideal for high-speed applications like electronic assembly.

- ESR6-500Z20: Offers a higher payload and 500 mm reach, suited for fast pick-and-place operations.

Collaborative Robots: Designed to work safely alongside human operators, combining precision and flexibility to enhance production efficiency.

- ECR5: 6-axis robot with a 5 kg payload and 900 mm reach. Features multi-level safety in both hardware and software, with sensitive collision detection enabling barrier-free human-machine collaboration. Note: Safety features are designed according to ISO 13849 PLD, Cat.3 standards.

Welding Robots: ARC10-1600: Specifically engineered for arc welding applications, with a 1600 mm reach, ensuring precision and high-quality welds.

- ARC12-2000: With a longer 2000 mm reach, suitable for welding larger components.

Painting Robots: Designed for automated painting applications, ensuring even coverage and reduced material waste.

- GR6150-1500: With a 15 kg payload and 1500 mm reach, this robot is tailored for Chinese SMEs, featuring an explosion-proof structure and standard painting software package. It includes integrated I/O peripheral points for easy integration and is especially suitable for metal parts, furniture, plastic parts, and other irregularly shaped items.

Palletizing Robots: Optimized for palletizing tasks, these robots offer speed and precision in load placement, boosting logistical efficiency.

- ER14-4-1600: 4-axis robot with a 15 kg payload and 1600 mm reach. Optionally available with a specific application software for simple programming and operation, enabling quick production startup. Also usable for handling tasks such as machine tending.

For a complete overview of the models and their technical specifications, please visit the product section of the official EFORT website.

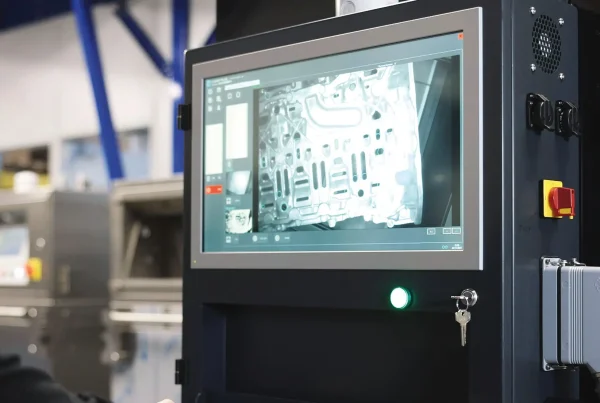

Software Controller and Hardware Control

The control software of EFORT robots, based on RTE firmware, enables efficient real-time task management. Users can program the robot using Ladder Diagram (IEC1131) for PLC control or Object Blocks for C++ development with an object-oriented approach. Additionally, programming in R3 | R provides advanced tools for motion control, addressing challenges such as synchronization, trajectory generation, and electronic cam management, with the ability to make real-time adjustments.

This architecture makes the system highly flexible and suitable for a wide range of industrial applications.

At the core of it all is ROBOX programming—a logic system developed by Robox S.p.A. (an Italian company specialized in the design and production of electronic controls). Below is a summary of its key strengths:

RTE Firmware

The base firmware, RTE (Real Time Extended), is installed on removable memory and enables the proper execution of various tasks.

Ladder Diagram (IECI1131)

- Allows real-time monitoring, editing, and creation of mathematical blocks.

- Fully integrates with Object Blocks.

- Provides access to an open PLC library.

Object Blocks

- Enables the development of any type of software using C++ with an object-oriented approach.

- Offers low-level access to the operating system.

- Programmers can modify existing Object Blocks to add new features (properties, methods, etc.) or reuse other existing Object Blocks.

R3|R – Structured Text with Motion Libraries

- Solves synchronization issues for any number of rotating and/or translating axes.

- Handles trajectory generation problems for multiple axes.

- Enables the programming of complex motion laws simply by writing their equations.

- Allows the creation of electronic cams.

- Supports real-time modifications.

User Controller and Electrical Cabinet Feature

Models for Die-Casting

The following videos showcase the operation of the ER50-2100 model within a production process at a client’s facility. Following the videos, a table presents all the technical specifications.

Download here the catalogue with all technical specifications of the models!

You can download the catalogue containing detailed technical specifications for EFORT robot models from their official website. The catalogue includes information on various robot series, such as SCARA, small, medium, and heavy payload robots, as well as welding and palletizing robots. Each model is accompanied by its respective flyer and 3D files for comprehensive technical insights.