Mambretti Tech Announces Distribution Agreement with Haitian Italia for Cold Chamber Die Casting Machines

Haitian Die Casting, the die casting division of the renowned Chinese industrial giant, manufactures 4,000 machines per year with highly automated production lines and cutting-edge technology. Haitian machines stand out for their robustness, versatility, and innovative design, ensuring stable, efficient, and safe production processes.

Who is Haitian?

For nearly 50 years, Haitian has been a leader in injection molding technology and has recently established itself as a high-value player in cold chamber die casting machines. Founded in 2016, Haitian Die Casting specializes in light alloy die casting machines, boasting an annual production capacity of approximately 4,000 machines.

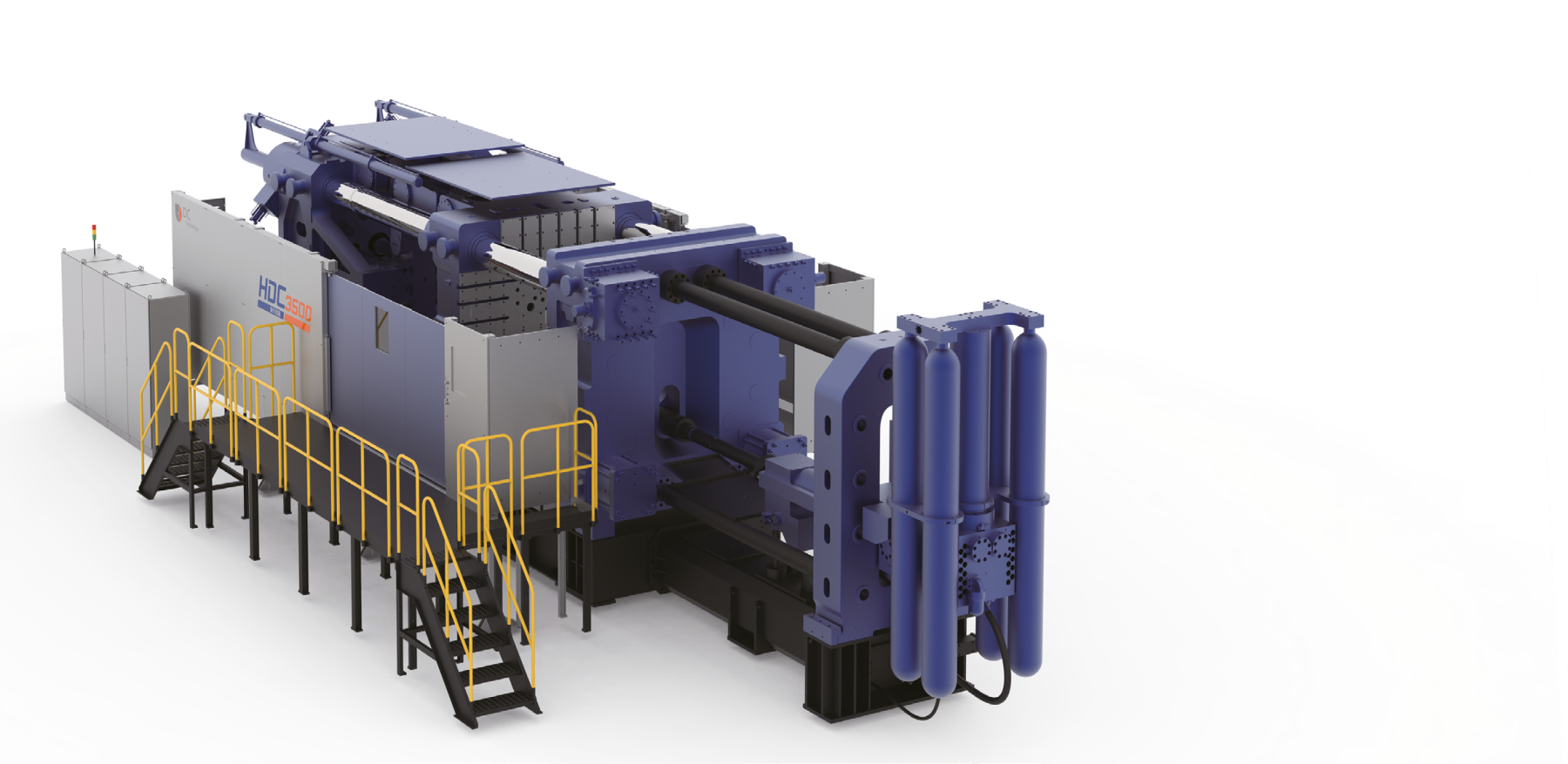

Haitian’s toggle-type die casting machines, ranging from 180 to 8,800 tons of clamping force, feature advanced real-time closed-loop control. From 2025, Haitian will introduce new magnesium alloy die casting machines equipped with an innovative injection system. This system loads molten metal through a hopper directly connected to the mold, eliminating direct contact between molten magnesium and air for enhanced safety and efficiency.

👉Haitian diecasting press: 180 to 850 Tons👈

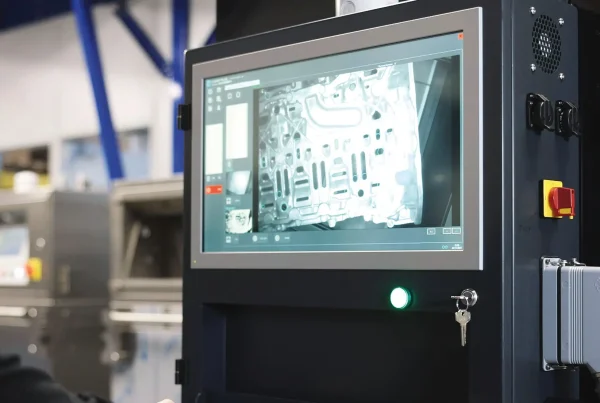

Even in compact models, Haitian machines excel in build quality and technological innovation. Equipped with an advanced injection system and an intuitive HMI interface, they offer the highest levels of safety and efficiency.

The three-platen clamping unit ensures structural strength and easy access to wear-prone components. High-quality materials, such as special alloy columns developed by the Haitian Material Research Institute and nitrided 38CrMoAl toggle pins, provide durability and reliability.

Haitian’s exclusive closing movement software optimizes the five-point mechanical structure, ensuring perfect synergy between pressure curves, mold-closing cylinder motion, and the clamping unit’s movement.

For maximum precision, the real-time dual closed-loop injection system dynamically adjusts injection parameters via advanced servo-valves and dedicated software, allowing separate control of speed and pressure.

👉Haitian diecasting press: 1,000 to 8,800 Tons👈

As the demand for aluminum and magnesium die cast components grows in automotive, EV battery production, and 5G communication, the need for large-scale, high-precision giga presses has also increased.

To meet this demand, Haitian Die Casting has established a state-of-the-art Technology Development Center, covering 5,000 m², dedicated to designing and manufacturing next-generation die casting machines featuring real-time closed-loop control.

These machines are equipped with automated melting furnaces, vacuum systems, mold temperature monitoring sensors, advanced robotics, and a dedicated material development lab. With intensive testing on product functionality, new materials, and emerging technologies, Haitian delivers high-tech die casting machines that combine efficiency, safety, and smart solutions for seamless operation.

📥 Download the full catalog with technical specifications.

For more information, contact us or visit the Mambretti.tech website👈